Whether you need tight-turns or ergonomic steering, reliable cart steering requires more than just high-quality casters. Understanding the mechanics behind steering systems can reveal why some designs excel in handling tight turns, and help you choose the right one for your facility. Jtec Industries makes it a priority to deliver effective cart steering technology that meets the diverse needs of the manufacturing world. Let’s explore the different types of tugger cart steering and their specific advantages.

Steering Styles

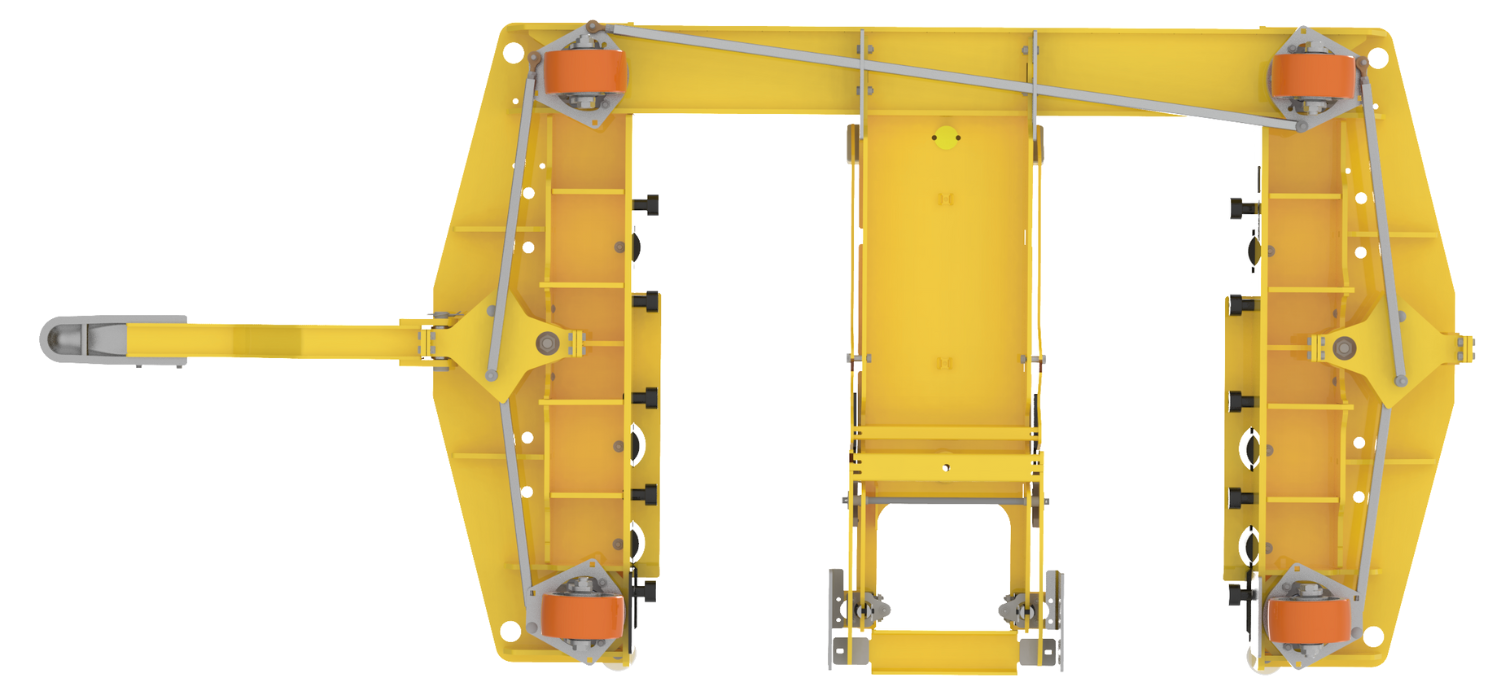

I. QUAD STEER

The best option for tight turns (even 6’ aisle-to-aisle) is Quad Steer. All four wheels are connected and work together, with the front pair pointing into the turn and the rear pair pointing outwards. This provides a consistent and calculated turn, which is extremely important when working in tight spaces and a train of multiple carts. Quad Steer creates a predictable follow path that can be relied on. Depending on your space, it can even accomplish a 180 degree turn.

This steering style is great for our CarryMax carts, which hold up to 20,000lb, and mother carts in our CarryMore tugger cart system.

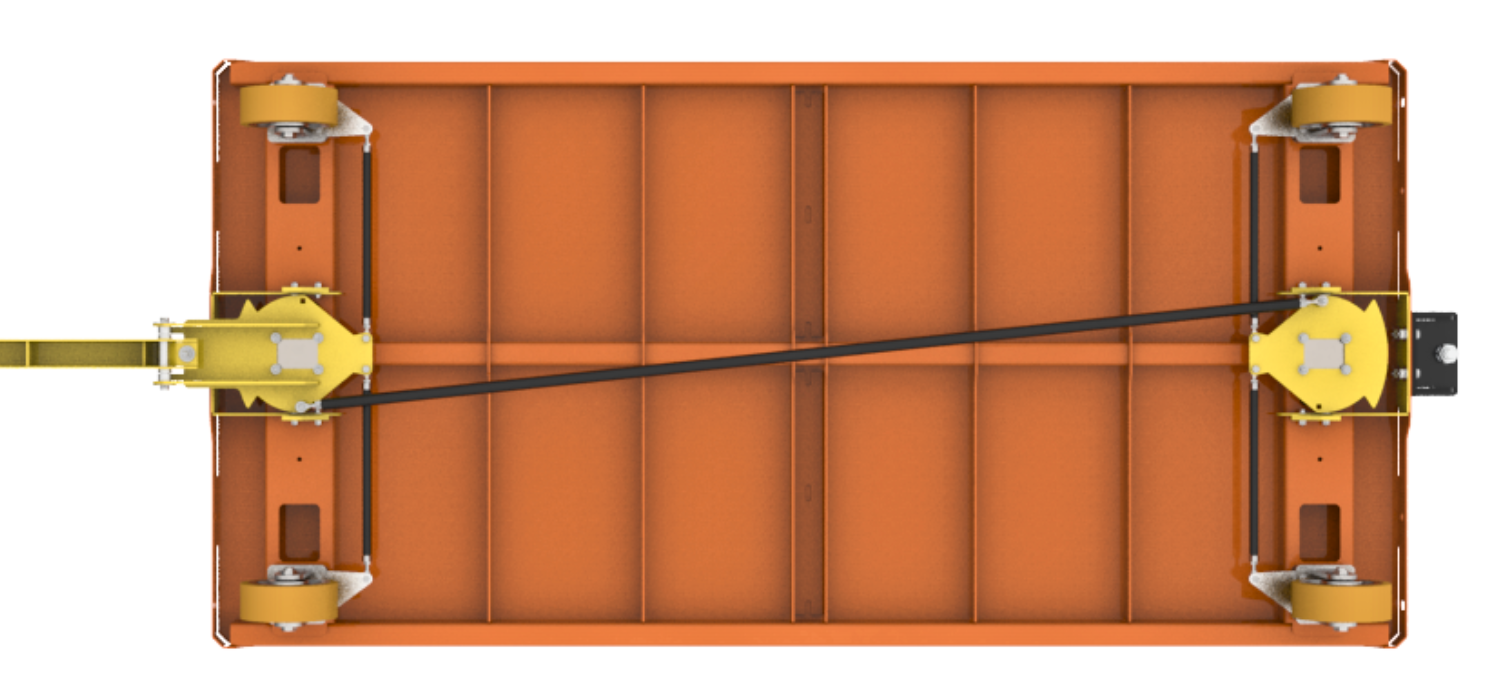

II. CENTER STEER

Secondly is Center Steer. The center casters are fixed, while the outer casters swivel, offering a balance between stability and maneuverability. While Quad Steer is is more reliable for turns and can take more weight, there are advantages to Center Steer. On top of being lower in price, it can pivot sharply for U-Turns without casters scrubbing, due to its two rigid casters in the center. This also means it has more mobility to be pushed or turned by hand. This is beneficial if you want the option to turn the mother cart manually, to have it load/unload from the other side of the train.

You will find Center Steer as a popular option for our CarryMore tugger carts. It is also available in a 6-wheel configuration with our light duty tongue and hitch carts, CarryLite.

III. REAR STEER

This is the best setup for push carts, such as our CarryLite tongue and hitch carts, or the many daughter cart options in the CarryMore system. It uses a combination of 2 swivel casters in the back for steering, and 2 rigid casters in the front for control. By mechanically lifting the daughter carts off the ground, Jtec’s CarryMore mother-daughter tugger cart system allows all of their daughter carts to be rear steer.

In other systems, daughter carts often touch the ground and thus need to have 4-swivel casters. But 4-swivel carts are notoriously difficult to push. This means that CarryMore’s ergonomic push carts can be comfortably steered by employees with less strain than other systems allow for.

Reach Out Today

When it comes to material handling, choosing the right steering system is critical. With Jtec’s solutions, you can be confident in reliable, consistent cart handling. These steering styles increase safety, efficiency, and often boost employee morale. To learn more, visit jtecindustries.com, or reach out using the form below.