In R&D, the old ways of doing things aren’t treated as if they’re written in stone. Traditional methods are put under a microscope and questioned: Is there a better way? The goal is always to find the most efficient process and to try and make it work. Whether it’s rethinking an outdated workflow, integrating new technology, or optimizing a process from the ground up, nothing is off-limits. It can include incremental improvements but it can also mean transforming how the industry operates, pushing boundaries when needed, and making breakthroughs that move the industry forward.

R&D: Engineering and Application

At Jtec, our R&D department is made up of a diverse selection of engineers who specialize in software, mechanical systems, electrical design, automation, and more. R&D experts collaborate to design innovative solutions that address the many unique challenges of material handling. They often work closely with customers to navigate issues and formulate lasting solutions. Each specialization brings a different perspective to the table, ensuring that every solution is technically sound while also scalable, and tailored to meet the evolving needs of the industry. Together, this diverse team is responsible for driving forward the technological advancements that shape the future of material handling.

Jtec’s R&D is constantly examining how different materials are being moved or handled across industries, looking for inefficiencies, and working to develop solutions. R&D also identifies safety risks and creates equipment that makes operations safer for workers. R&D evaluates the best approach to a customer’s need, rigorously prototyping and testing possible solutions. After thorough refinement these concepts can become a game-changing reality that advances a specific facility or the entire industry.

The process of bringing a solution to the market varies, but often looks something like this:

1. Idea Generation: Engaging with clients, industry experts, and internal teams to brainstorm and gather potential concepts.

2. Feasibility Study: Assessing the practicality of the ideas through initial technical research and market analysis.

3. Prototype Development: Creating early models to test functionality, user experience, and design refinements

4. Rigorous Testing: Subjecting prototypes to real-world conditions to ensure durability, safety, and performance.

5. Feedback Loop: Collecting input from customers, field testers, and internal teams to iterate on the design.

6. Launch and Marketing: Finalizing the product, developing marketing strategies, and deploying the solution to the market.

Proven Solutions

The results speak for themselves. Innovations like the all-mechanical CarryMore Mother-Daughter tugger cart system and our CarryMatic automated transfer solutions are products of R&D, born from a deep understanding of the challenges faced by customers. These aren’t just technical improvements—they are game-changing solutions that make the entire material handling process more efficient, safe, and cost-effective.

CarryMore was developed for an industry that had become too reliant on the redundancy and dangers of forklift transportation. Our system allows for an entire train of materials to be tugged by an AGV, rather than one pallet at a time. Additionally, our patented Elemate technology allows daughter carts (the carts pushed by employees) to be mechanically lifted off the ground inside the mother cart while being tugged. This improves the lifespan of the daughter carts and creates a more efficient tugging experience.

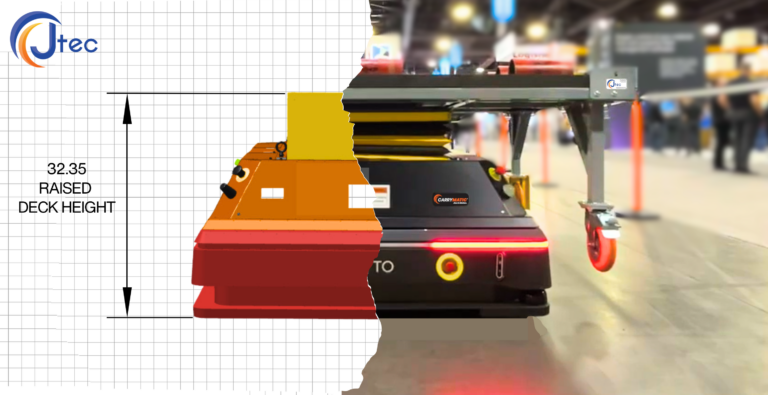

CarryMatic, our autonomous product line, was developed for industries that want to take safety and efficiency to the next level. R&D has collaborated with many companies to understand their specific needs. Some examples entail the need to alleviate bottlenecks, improve precision in handling delicate or heavy loads, and the reduction of injury risks. These needs, along with the desire for scalable and flexible automation, led to the development of CarryMatic. Whether you need an automated power roller system or an autonomous scissor lift, we have you covered. With Jtec, you can automate just about any stage of material movement.

Our Newest Innovation

Jtec’s R&D team has worked tirelessly to develop a solution for safely and efficiently moving fully-loaded server racks in data centers. These racks can weigh thousands of pounds, posing significant safety risks during transport. Hyperscalers, or large-scale data centers, often prefer to move these racks fully loaded to meet operational needs. Collaborating with the Open Compute Project (OCP), our team aimed to standardize data transport with an automated solution that could transform data center operations. Jtec is proud to announce that our new cart successfully addresses this problem, and can automatically transport two fully loaded server racks, boasting a weight capacity of 7,000lb.

Reach Out Today

It is through R&D that the world moves forward, constantly improving beyond what it was yesterday. It’s a commitment to never settling for “good enough”—to always push for the best possible solution. At Jtec Industries, we don’t just solve today’s challenges; we anticipate tomorrow’s needs, ensuring that innovation continues to elevate how we live and work. Visit our website at jtecindustries.com or reach out using the form below.