Most facilities would greatly benefit from a tracking analysis for their tugger cart or AMR transport route. By understanding cart movements with our virtual tracking analysis, you gain valuable insights on safety, efficiency, and how to optimize available floor and aisle space. With this data-based approach, you can greatly improve your layout planning and operational effectiveness. This is done by utilizing unused space for product storage and process machinery deployment.

What is a Tracking Analysis?

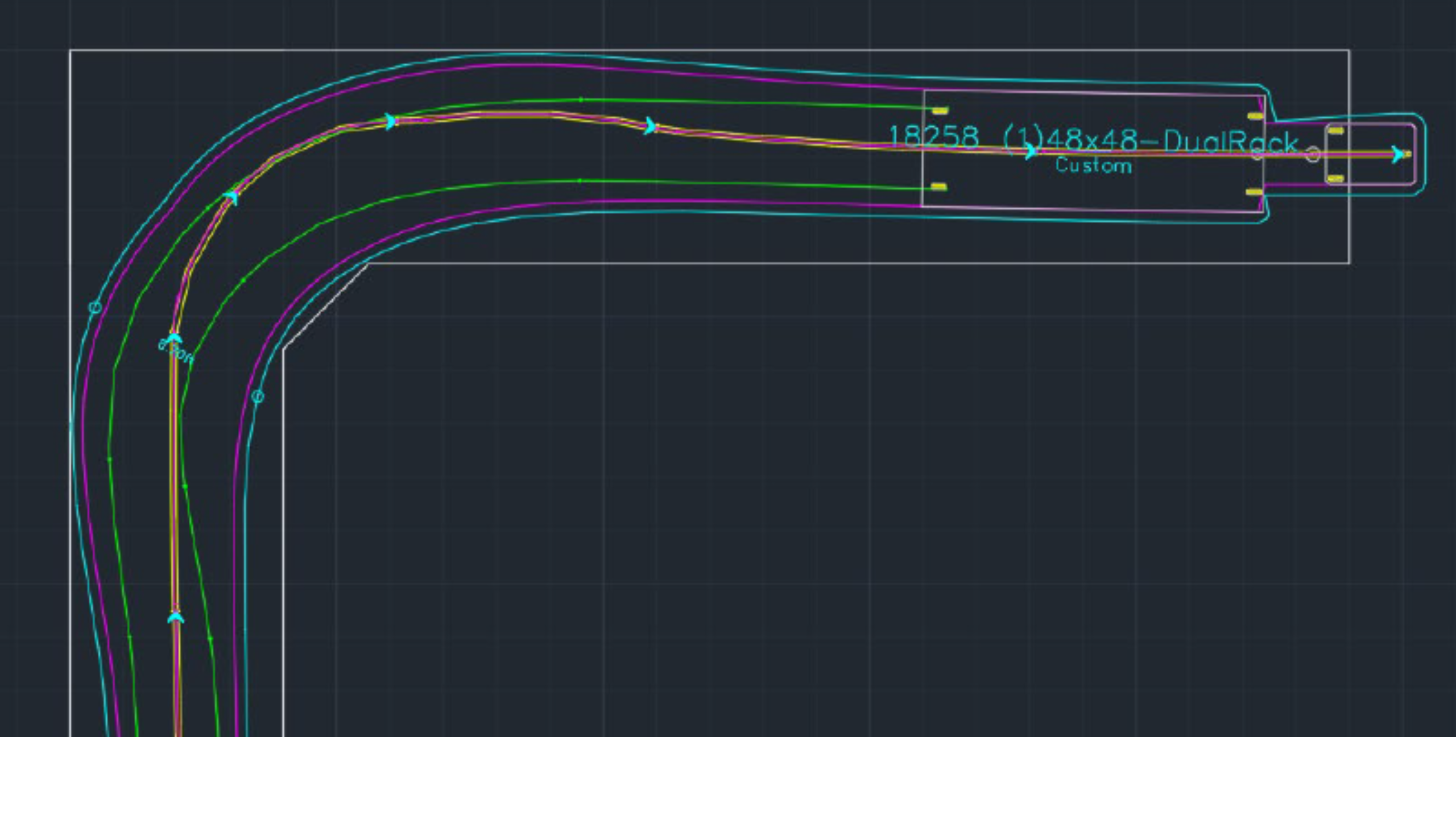

In the analysis a map is created that serves as a precise evaluation of cart movements within a facility. This is extremely beneficial for multiple reasons. The analysis helps us decide between the ideal cart and steer style. It also calculates aisle and corner requirements, as well as mapping out unused space. Facility floor and aisle space are invaluable assets in a manufacturing environment. Reducing unused areas allows businesses to maximize the available room for products and essential machinery. Many existing aisles are often wider than necessary, presenting an opportunity to reclaim space for various applications.

Why it Works

The analysis works because of the key information we utilize. Key characteristics of tugger carts are put into the analyzation, including:

- Track Width: The distance between the wheels on the same axle.

- Wheelbase: The distance between the front and rear axles.

- Overall Cart Size: The total dimensions of the cart.

- Overhangs: Any extensions beyond the cart’s main body.

These parameters are combined with accurate cart steering geometry to generate a theoretical tracking model of the cart’s movement throughout the plant.

Multiple Cart Trains

When multiple carts are linked together, the analysis extends to assess the impact on aisle widths and turning radii. By doing so, significant gains can be achieved by optimizing aisle widths and chamfering corners as necessary. This approach can lead to substantial improvements in space utilization and operational efficiency.

Swept Path

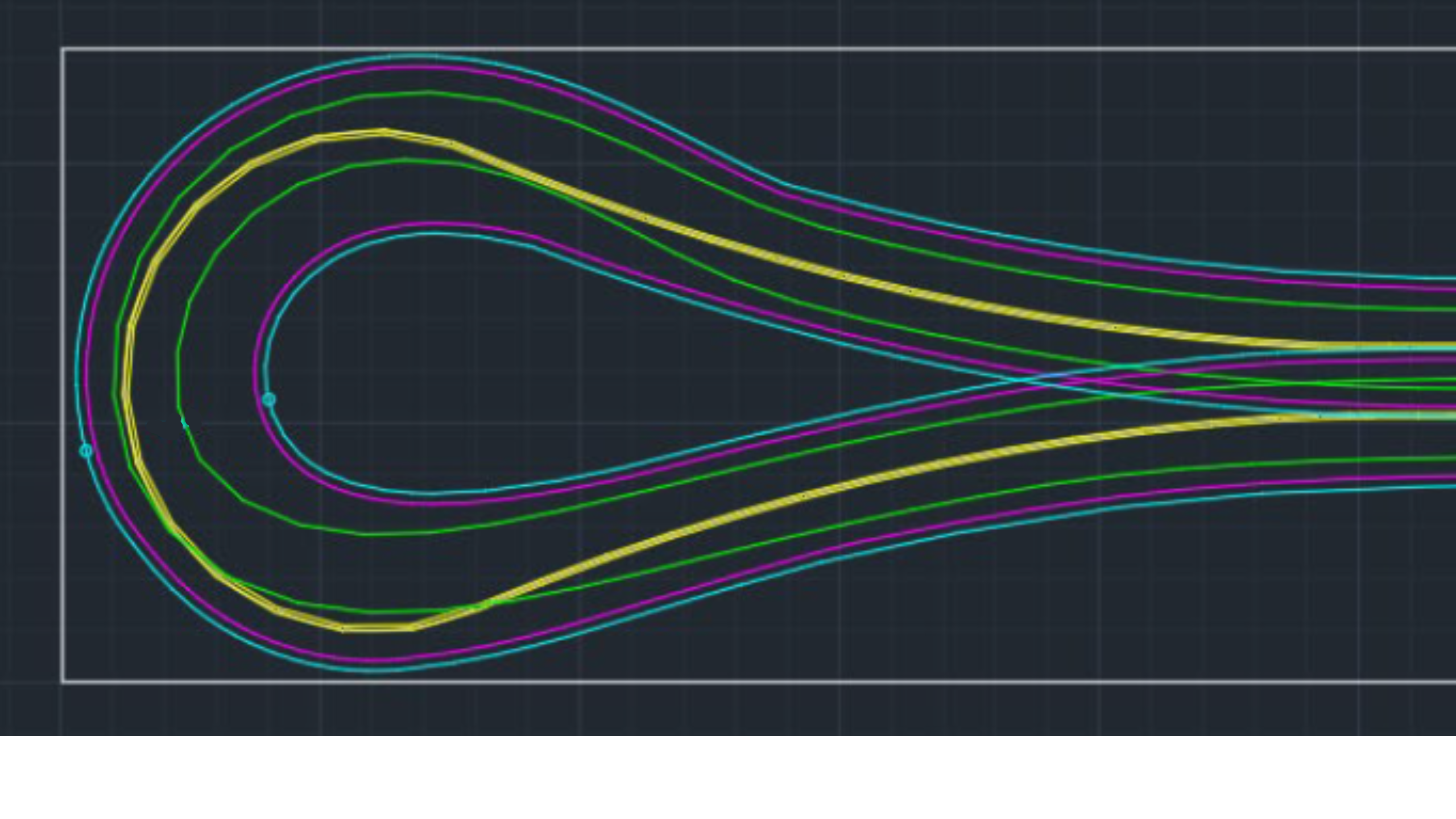

A Swept Path analysis is the evaluation and calculation of the space required when a vehicle makes turning maneuvers. This information is extremely important when tugging. Jtec’s system performs this analysis for various steering configurations:

- Rear Steer

- Center Steer

- Quad Steer

This analysis can be conducted over generic turning scenarios or within a detailed plant layout to simulate actual routes.

U-Turns and Aisle Widths

For scenarios requiring U-turns at the end of an adjacent aisle, the system determines the minimum width of the feed aisle and the required width of the end aisle to ensure successful U-turns. This capability is crucial for optimizing space while maintaining maneuverability.

Alignment with Mating Stations

The analysis also evaluates the necessary distance from a corner to ensure that a cart train is properly aligned with mating stations from either side. This assists in conveyor lane setup, reducing excess dead space before the first lane, and enhancing overall efficiency.

Safety and Visual Aids

In cases where clients are unable to alter their aisle configurations, Jtec’s system can determine the maximum cart size that can safely navigate the plant, incorporating a built-in safety buffer on each side of the train. Visual representations and caution areas for potential close contact points are provided to ensure safe and efficient operations.

Reach Out Today

Jtec’s tracking analysis is unique in that it offers a strategic, data-based approach to enhancing efficiency and optimizing cart movements within a facility. Let us help you help you maximize your facility’s space and increase your confidence in your operation. Do not hesitate to reach out today. We are here and happy to help.